![stamping and bending parts stamping and bending parts]() Stainless Steel Stamping

Stainless Steel Stamping Stainless steel stamping parts are industrial products manufactured based on stainless steel materials such as 304 through precise stamping processes. Its processing procedure includes material cutting, stamping forming, deburring, surface treatment and other processes, and uses electrochemical processing, rolling processing and other technologies to achieve ultra-precision surface treatment. The thickness of the product can be customized according to the application scenario. In the industrial field, a 1.5mm specification is commonly used, while kitchenware products mostly adopt a 0.8mm thickness. It is mainly applied in the manufacturing of automotive parts, electronic equipment shells, home appliance accessories and other fields. In 2024, a new invention patent was added, involving multi-specification synchronous positioning grinding technology, which can achieve batch post-processing of workpieces of different diameters.

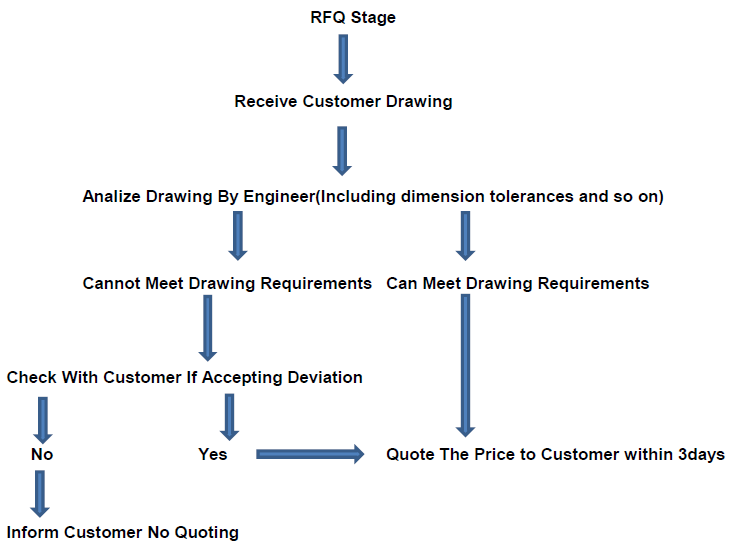

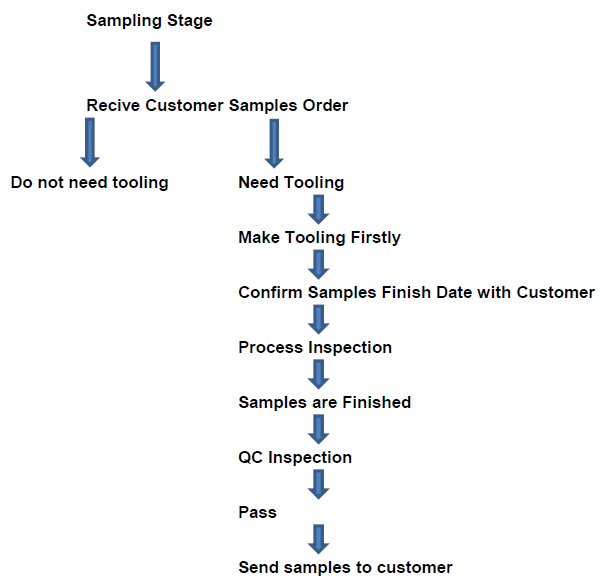

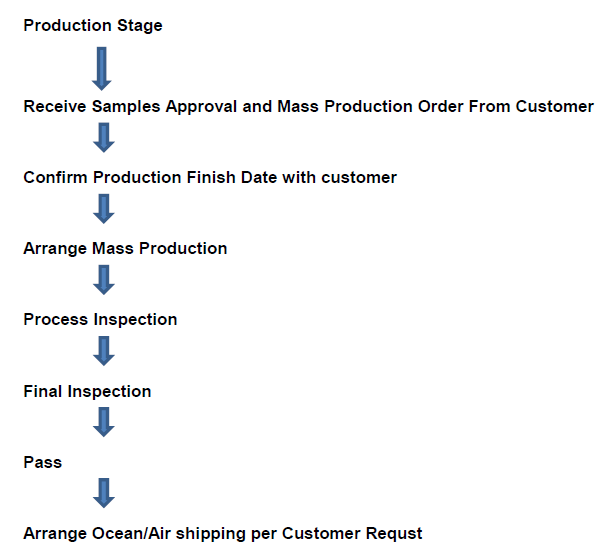

All of our stainless steel stamping and bending components are customized according to customer's drawings or samples. Please find below chart to show how we handle with these tailored design metal products:

![RFQ阶段 RFQ阶段]()

![samples阶段 samples阶段]()

![production阶段 production阶段]()

Product Advantage of 304SS Custom Stamped and Bent Component:

Superior Corrosion Resistance: Inherent property of 304 stainless steel, ideal for harsh/moist environments.

High Strength & Durability: Provides structural integrity and long service life.

Excellent Hygiene: Non-porous, easy-to-clean surface, perfect for food, medical, and pharmaceutical uses.

Precision Fit & Function: Engineered to exact specifications and tight tolerances for reliable performance.

Custom Design Flexibility: Stamped and bent to create complex shapes meeting unique application needs.

Consistent Quality: Precision manufacturing ensures uniformity and repeatability in production.

Good Formability: 304SS allows for complex stamping and bending without compromising material properties.

High-Temperature Resistance: Suitable for applications involving elevated temperatures.

Cost-Effective Production: Stamping and bending are efficient processes for high-volume or custom runs.

Wide Applicability: Versatile for demanding sectors like automotive, industrial, electronics, and more.

Product use of 304SS Custom Stamped and Bent Component:

Food Processing Equipment: Housings, brackets, chutes, and conveyors requiring hygiene, corrosion resistance, and washdown capability.

Medical & Pharmaceutical Devices: Surgical tools, instrument frames, enclosures, and fluid handling parts needing sterility and chemical resistance.

Industrial Machinery: Guards, supports, connectors, and structural parts in corrosive or high-wear environments.

Automotive Systems: Exhaust components, sensor mounts, brackets, and fuel system parts demanding heat and corrosion tolerance.

Electronics & Enclosures: Precision chassis, shielding, heat sinks, and connectors requiring EMI protection and dimensional stability.

HVAC & Plumbing: Ductwork fittings, vents, clips, and couplings exposed to moisture and temperature variations.

Architectural & Fabrication: Decorative trim, custom fixtures, and functional hardware where aesthetics meet durability.

Packaging:

![包装组图_meitu_3 包装组图_meitu_3]()

FAQ:

1Q: What is your minimum order quantity (MOQ) for custom components?

1A: Our MOQ is flexible and project-dependent. We accommodate both prototyping/low-volume runs and high-volume production. Contact us with your requirements for a tailored solution.

2Q: What file formats and information do you require for quoting?

2A: We require 2D drawings (PDF, DWG, DXF) or 3D models (STEP, IGES, SOLIDWORKS) with critical dimensions, tolerances, material specs (304SS), surface finish, and quantity. Design intent notes are helpful.

3Q: What is your typical lead time, and do you offer expedited options?

3A: Standard lead times range from 4-8 weeks after design approval. Expedited options (2-4 weeks) are available for urgent projects – contact us for feasibility and cost.

4Q: Can you provide material certifications and comply with industry standards?

4A: Yes. We supply full Mill Test Certificates (MTCs) for 304SS. Our processes comply with ISO 9001, and we meet FDA/USDA requirements for food/medical applications upon request.

5Q: Do you offer prototyping or small-batch sampling?

5A: Absolutely. We provide rapid prototyping (CNC, short-run stamping) and low-volume sampling to verify design, fit, function, and quality before full production commitment.