We make the stamping parts according to customer's drawings. Each of our product is the unique and cannot be availabe in the existing markets.

![RFQ阶段 RFQ阶段]()

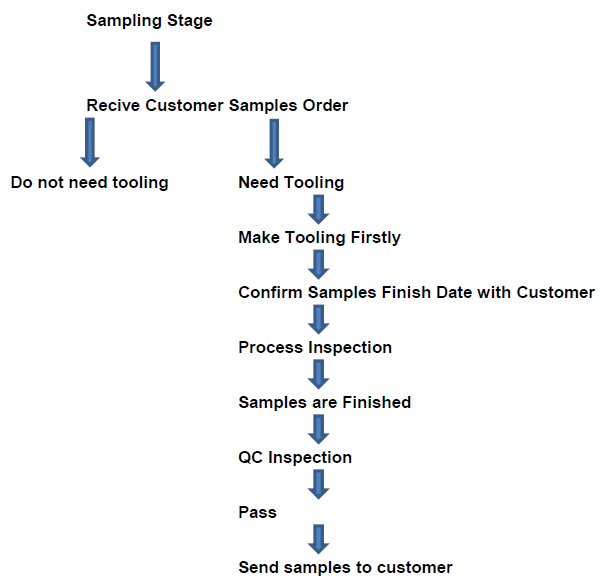

![samples阶段 samples阶段]()

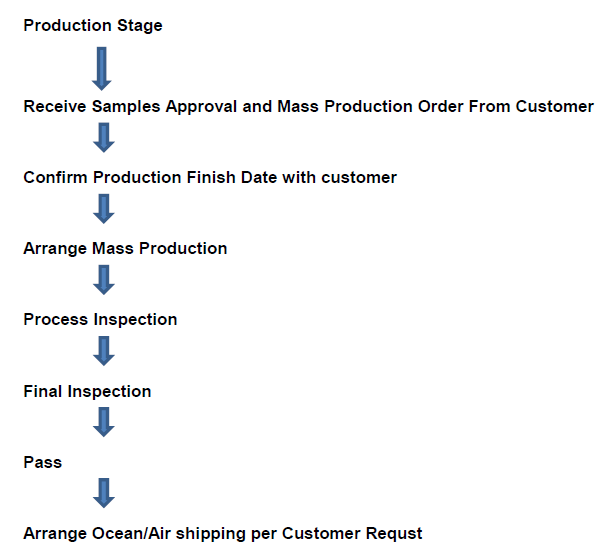

![production阶段 production阶段]()

Product Advantages of Carbon Steel Stamped Plate:

Substrate performance: The use of high-quality low carbon steel (such as Q235 or SPCC), cold rolling process to improve the surface finish and mechanical strength, tensile strength of 300-400MPa, can withstand the dynamic load in high-pressure gas transmission.

Galvanizing protection: surface hot dip galvanizing (zinc layer thickness ≥50μm) or electric galvanizing treatment, in line with ASTM A653/A924 standards, effective barrier water vapor, hydrogen sulfide and other corrosive media, salt spray test ≥500 hours without red rust, adapt to coastal, underground and other humid environment.

Surface strengthening: Optional passivation or sealing coating after galvanizing, surface hardness up to HV150-200, wear resistance more than 3 times higher than ordinary carbon steel, resistance to frequent mechanical operations (such as thousands of daily start and stop).

Product Use of Carbon Steel Stamped Plate:

Oil and gas collecting station equipment:Position and secure pressure gauges and safety valves in wellhead environments containing hydrogen sulfide and high humidity to ensure reliable linkage between monitoring and emergency shut-off devices.

City gas regulator: Integrated into the pressure regulator in residential or industrial areas, it supports the rapid installation and Angle calibration of flowmeters and cut-off valves, and ADAPTS to frequent start-stop conditions.

LNG receiving station control system: In low temperature (-162 ° C) liquefied natural gas environment, bearing instruments and actuators are positioned to withstand extreme temperature differences and condensation corrosion.

Chemical plant explosion-proof control unit: Applied to Zone 2 explosion-proof area, fixed explosion-proof solenoid valve, sensor, to meet the safety compliance requirements in flammable and explosive environment.

Packaging:

![包装组图_meitu_3 包装组图_meitu_3]()

FAQ:

1Q: What is a zinc plated carbon steel indexing plate used for?

1A: To provide accurate indexing and positioning.

2Q: How is the zinc plating beneficial for a carbon steel indexing plate?

2A: Zinc plating enhances its corrosion resistance, ensuring durability and longevity in gas transmission applications.

3Q: What is the leadtime for a steel stamped products?

3A: 4 weeks.

4Q: Can you provide free samples for customer to approve the tooling?

4A: Yes, we can provide 3pcs free samples, but customer needs to afford the freight cost.

5Q: Are these stamping parts customizable to specific gas transmission console requirements?

5A: Yes, our steel stamping parts can be customized according to your specifications for a perfect fit and functionality.