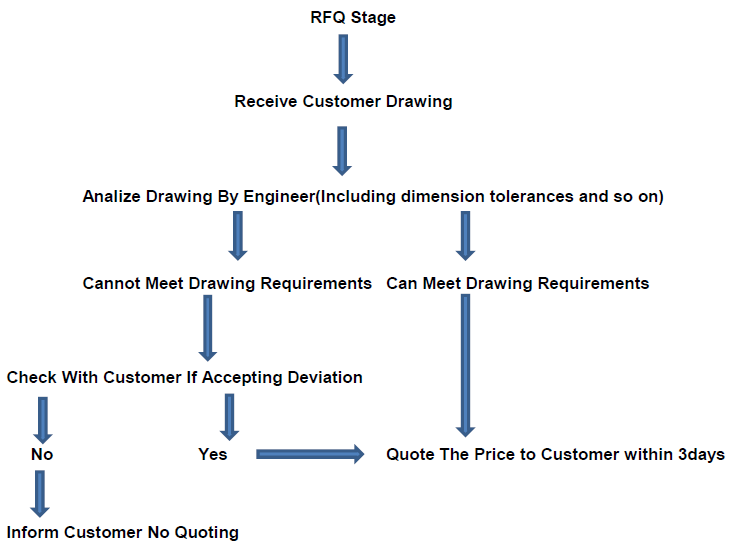

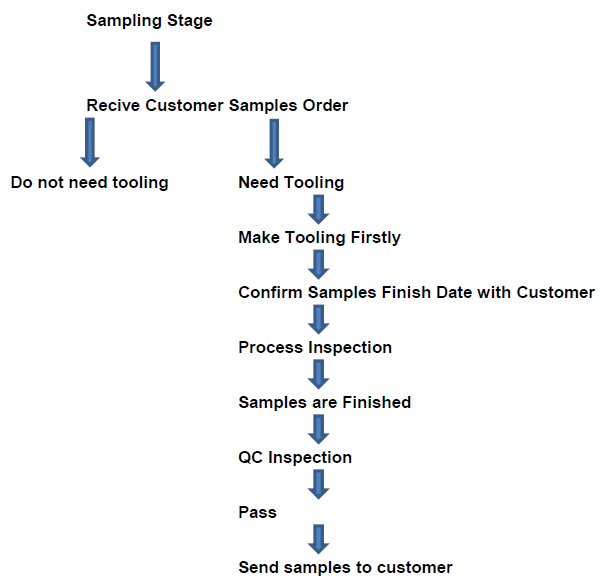

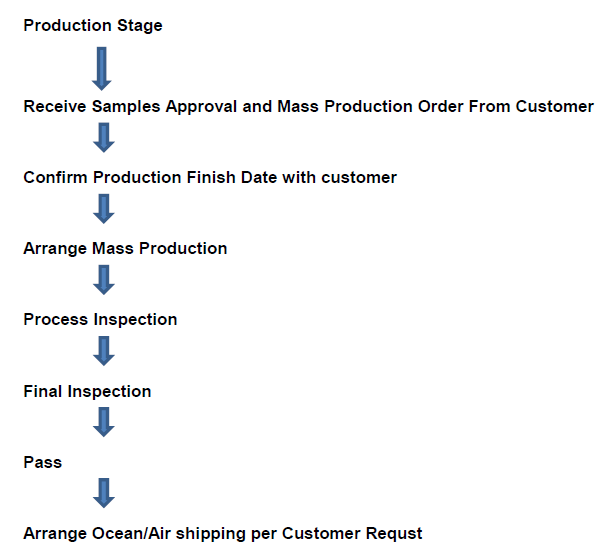

All of our die casting parts are custom made according to customer design. Please find below our brief introduction about our Parts Custom Processing Flow Chart.

![RFQ阶段 RFQ阶段]()

![aluminum diecasting parts aluminum diecasting parts]()

![aluminum die casting parts aluminum die casting parts]()

Product Advantage of Aluminum Alloy Die Casting Parts:

Lightweight and high-strength:Aluminum alloy material significantly reduces component weight while maintaining excellent mechanical properties and improving motor energy efficiency;

Excellent durability: Powder coating provides excellent corrosion resistance, wear resistance and high temperature resistance, extending service life in harsh environments;

Precision and stability:High pressure die casting process ensures dimensional accuracy of complex structural components and stability under long-term load;

Environmental safety :RoHS certified coating without harmful substances, both electrical insulation, to ensure safe operation and environmental compliance;

Cost-effectiveness: The integrated molding process reduces secondary processing and, combined with long life, significantly reduces overall maintenance costs.

Product use of Aluminum Alloy Die Casting Parts:

Automotive industry: New energy vehicle drive motor shell, sensor bracket, battery cooling module;

Industrial equipment: Automatic production line motor shell, pump valve assembly, mechanical transmission system precision structure;

Consumer Electronics :Drone motor frame, smart home appliance motor base, power tool protective cover;

Energy field:Wind turbine control unit housing, solar equipment connector;

Rail transit:Heat dissipation parts of train traction motor, shielding structural parts of signal equipment.

Its lightweight, weather resistance and electromagnetic compatibility are especially suitable for high vibration, high temperature and harsh working conditions.

Packaging:

![包装组图_meitu_3 包装组图_meitu_3]()

FAQ:

1Q: Does it meet international environmental standards? Does it contain lead or other hazardous substances?

1A: The products have passed RoHS certification, the coating is lead free and heavy metals free, and fully comply with environmental regulations to ensure safe application in the global market.

2Q: Can you customize other colors or non-standard sizes?

2A: Support color and size customization, provide Pantone color card color selection, and can adjust the die casting mold according to customer drawings to meet individual needs.

3Q:What is the MOQ? How long is the lead time?

3A: Regular order MOQ is 500 pieces, custom order can be negotiated; Sample 7-15 days, mass production cycle 3-4 weeks (depending on complexity).

4Q: What materials commonly use die casting parts?

4A: A380 aluminum ally, A360 aluminum alloy, ADC 12 aluminum alloy and so on.

5Q: Can you provide free samples for customer to approve the tooling?

5A: Yes, we can provide 3pcs free samples, and customer only needs to pay for the freight cost.