Materials pro sheet metallum partes

Materials pro sheet metallum partes

The commonly used materials for sheet metal parts mainly include stainless steel (SUS304/SUS301), galvanized steel sheets (SECC/SGCC), cold-rolled steel sheets (SPCC), aluminum sheets and aluminum alloys, copper and copper alloys, etc. The specific choice should be determined based on product functions, environmental requirements and processing techniques.

Aliquam Steel Series

Sus304: High Nickel contentus, cum corrosio resistentia (acidum et alkali resistentia), calor resistentia et excellens mechanica proprietatibus, quod est commune materiam pro familia adjumenta et kitchenware.

Sus301: Minimum Chromium contentus sed praeclara elasticitate, idoneam elastica partes ut vere laminis et protegit tegit.

Galvanized Steel sheet.

Electroplated galvanized sheet (SECC): Frigus-advolvit Steel sheet quod fuit electroplated, cum lenis et corrosio-repugnans superficiem, late usus est ad inclusi electronic products (ut computatrum casibus).

Hot-galvanized sheet, (SGCC) densior cadmiae coating (tractata in fusum cadit balneum ad circiter CDLX ° C), princeps duritia sed pauper ductility, idoneam in velit structural partium.

Frigus-advolvit ferro laminam.

SPCC: et lowest sumptus basi materia, facile ad formare sed postulat superficiem praesidium (imbre pictura / electroplating), crassitudine ≤3.2mm, idoneam ordinaria structural partes.

Aluminium et Aluminium Alloys.

A5052 / (VI) LXI: Maluit pro Lightweight, melior electrica conductivity quam aeris (in eodem pondere), requirit anodizing ad auctus corrosio resistentia, communiter in calido et decorarat et exornantur.

Aeris et aeris alloys.

Aes / Bronze: optimum electrica conductivity, idoneam ad connectors et protegit opercula, sed altius pretium

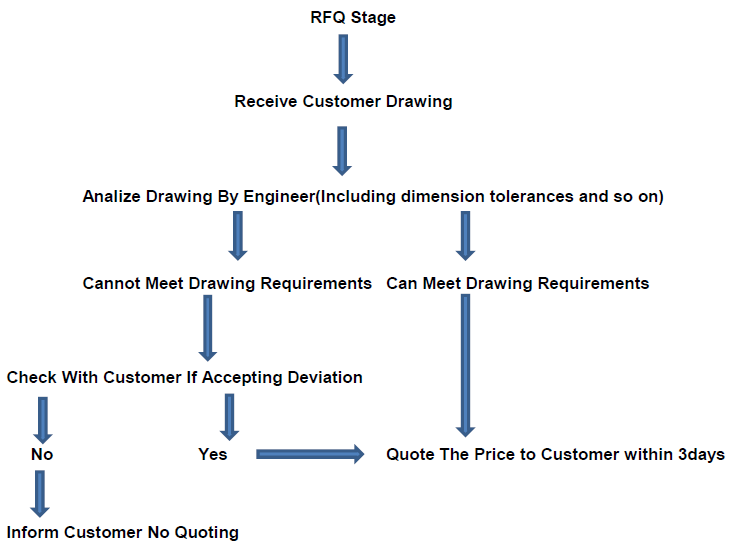

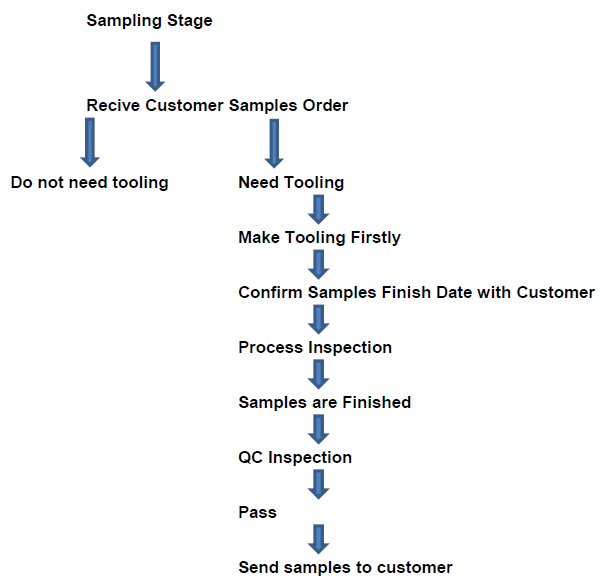

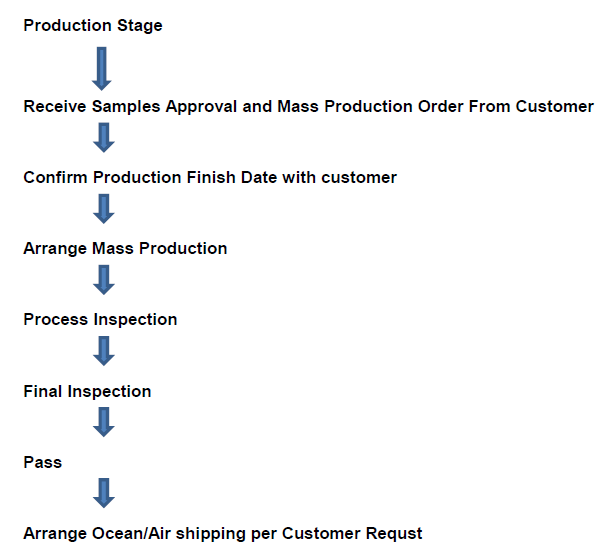

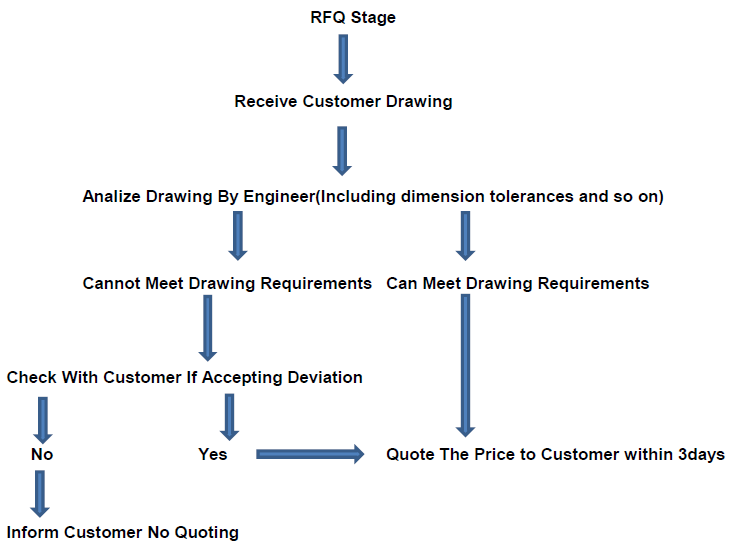

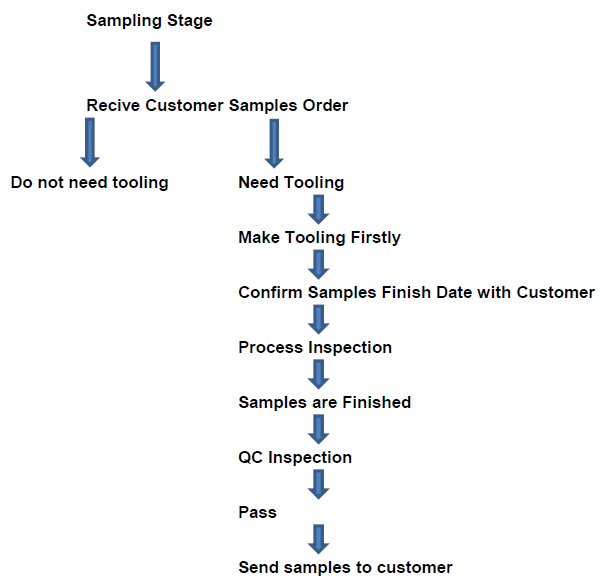

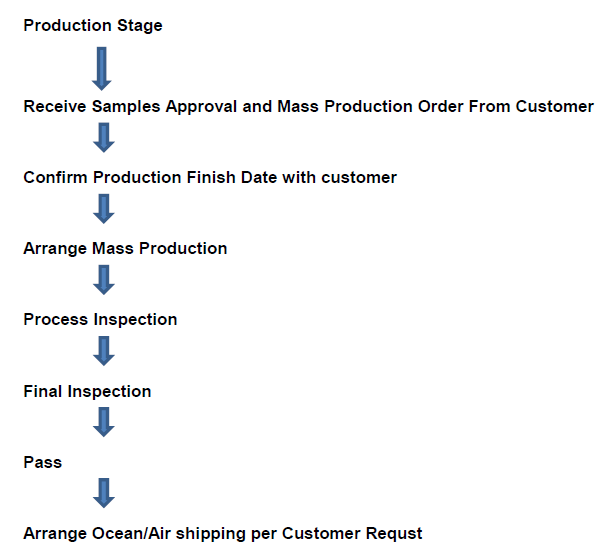

Nostrum opus fluxus chart pro customized welding et flectens products ut infra:

Product commodum de mos ferro fabricae partes:

Conquer corrosio: Zinc plating clypeos partes a rubigo, cursus Vivacitas etiam in dura ambitus.

Precision perfectis, stricta-tolerantia tendentes & Welding praestitus perfecta fit et munus omne tempus.

Built lenta: praecisione, machinatus cum robust strictis articulis liberavit exceptionalibus viribus et diuturnitatem.

Sailor-factum solutions, ut partes disposito et fabricata prorsus pro unique application.

Long-term valorem: superior rorum resistentia et diuturnitatem minimize supplementum, maxima tua Roi

Product usum mos ferro fabricatione partes:

Industrial Machinery: Frames, sustinet, et Housings postulat corrosio resistentia et structural integritas.

Electrical Clubinets & Cabinets: tutela Casings requiring Weatherproofing et precise Conventus.

Construction & structural elementa: uncis, adstringit, et sustinet expositae velit elementa.

Automotive components: engine uncis, chassis partes et jactu aggeris repetita vibratio resistentia.

Agricultural Equipment: Dura partes resistente chemicals, humorem et gerunt.

Material Tractantem Systems: TRADUCTOR tabulae, trollleys et robust onus-afferentem components.

Packaging:

FAQ:

1Q: Quam effective est cadmiae plating contra rubigo?

1a: nostri cadmiae plating providet robust corrosio resistentia, idoneam ad humidum, industriae, aut velit environments. Est typically offers 5-15 annis tutela fretus patefacio, significantly extendendo pars lifespan vs. spiraculum ferro.

2Q: Quid tolerances potestis consequi cum praecisione flectens et welding?

2A: Nos teneat stricta tolerances of ± 0.5mm (± 0.020 ') pro flexionibus et Welding. Provectus CNC apparatu ensures consistent accurate ad universa geometries et fideles conventus.

3Q: Quid est vestri minimum ordinem quantitas (MOQ)?

3A: Non accommodare et prototypum et productionem fugit. MOQ animi ad humilis ut L partes pro vexillum projects, cum flexibilitate pro mos aestimationes. (Prototypum MOQs ut infra).

4Q: Quid est typical plumbum tempore?

4A: Latin plumbum tempus 2-4 septimanas a consilio probat. Complexu aut alta volumina extendat. Prioritize urgente petitiones et providere firma timelines upfront.

5Q: Quid ergo tu determinare Morbi cursus sapien?

5A: Morbi cursus sapien pendent:

• Material Volume & Type

• Pars Complexity (flectit, Welds)

• Platis Crassitudine / Specifications

• Ordinis

Fees post recensendis drawings / Species.