![steel fabrication parts steel fabrication parts]() Materials for Sheet Metal Parts

Materials for Sheet Metal Parts The commonly used materials for sheet metal parts mainly include stainless steel (SUS304/SUS301), galvanized steel sheets (SECC/SGCC), cold-rolled steel sheets (SPCC), aluminum sheets and aluminum alloys, copper and copper alloys, etc. The specific choice should be determined based on product functions, environmental requirements and processing techniques.

Stainless steel series

SUS304 : High nickel content, combined with corrosion resistance (acid and alkali resistance), heat resistance and excellent mechanical properties, it is a common material for household appliances and kitchenware.

SUS301 : Low chromium content but excellent elasticity, suitable for elastic parts such as spring plates and shielding covers.

Galvanized steel sheet .

Electroplated galvanized sheet (SECC) : Cold-rolled steel sheet that has been electroplated, with a smooth and corrosion-resistant surface, is widely used for enclosures of electronic products (such as computer cases).

Hot-dip galvanized sheet (SGCC) : Thicker zinc coating (treated in molten zinc bath at about 460 ° C), high hardness but poor ductility, suitable for outdoor structural parts.

Cold-rolled steel plate .

SPCC : The lowest cost base material, easy to form but requires surface protection (spray painting/electroplating), thickness ≤3.2mm, suitable for ordinary structural parts.

Aluminium and aluminium alloys .

A5052/6061 : Preferred for lightweight, better electrical conductivity than copper (at the same weight), requires anodizing for enhanced corrosion resistance, commonly found in heat sinks and decorative parts.

Copper and copper alloys .

Brass/Bronze : Excellent electrical conductivity, suitable for connectors and shielding covers, but higher cost

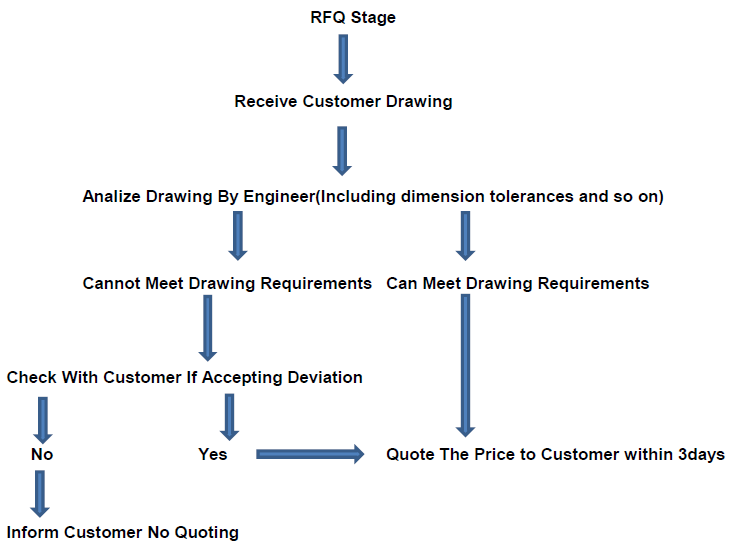

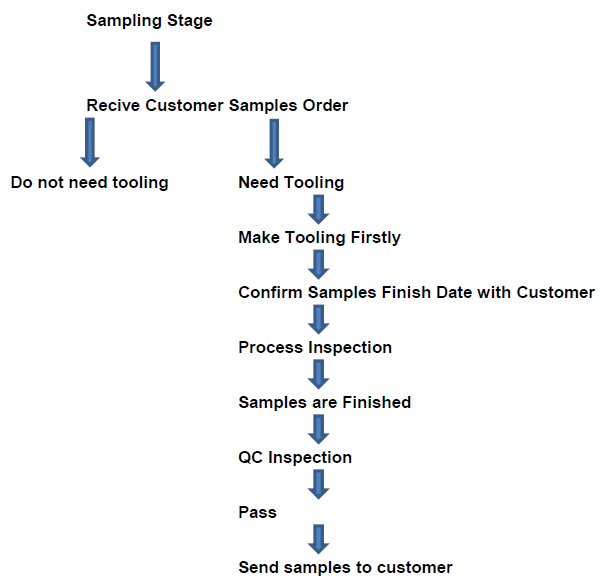

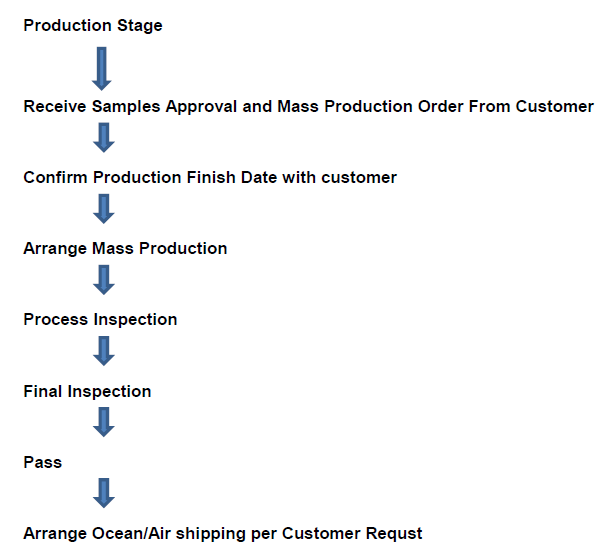

Our work flow chart for the customized welding and bending products as belows:

![RFQ阶段 RFQ阶段]()

![samples阶段 samples阶段]()

![production阶段 production阶段]()

Product Advantage of Custom Steel Fabrication Parts:

Conquer Corrosion: Zinc plating shields parts from rust, ensuring longevity even in harsh environments.

Precision Perfected: Tight-tolerance bending & welding guarantee perfect fit and function every time.

Built Tough: Precision-engineered steel with robust welded joints delivers exceptional strength and durability.

Tailor-Made Solutions: Get parts designed and fabricated exactly for your unique application.

Long-Term Value: Superior corrosion resistance and durability minimize replacements, maximizing your ROI

Product use of Custom Steel Fabrication Parts:

Industrial Machinery: Frames, supports, and housings demanding corrosion resistance and structural integrity.

Electrical Enclosures & Cabinets: Protective casings requiring weatherproofing and precise assembly.

Construction & Structural Elements: Brackets, braces, and supports exposed to outdoor elements.

Automotive Components: Engine brackets, chassis parts, and mounts needing vibration resistance.

Agricultural Equipment: Durable parts resisting chemicals, moisture, and wear.

Material Handling Systems: Conveyor frames, trolleys, and robust load-bearing components.

Packaging:

![包装组图_meitu_3 包装组图_meitu_3]()

FAQ:

1Q: How effective is the zinc plating against rust?

1A: Our zinc plating provides robust corrosion resistance, suitable for humid, industrial, or outdoor environments. It typically offers 5–15 years of protection depending on exposure, significantly extending part lifespan vs. uncoated steel.

2Q: What tolerances can you achieve with precision bending and welding?

2A: We hold tight tolerances of ±0.5mm (±0.020") for bending and welding. Our advanced CNC equipment ensures consistent accuracy for complex geometries and reliable assembly fit.

3Q: What is your minimum order quantity (MOQ)?

3A: We accommodate both prototype and production runs. MOQ starts at as low as 50 pieces for standard projects, with flexibility for custom evaluations. (Prototype MOQs may be lower).

4Q: What is your typical lead time?

4A: Standard lead time is 2–4 weeks from design approval. Complex projects or high volumes may extend this. We prioritize urgent requests and provide firm timelines upfront.

5Q: How do you determine pricing?

5A: Pricing depends on:

• Material volume & type

• Part complexity (bends, welds)

• Plating thickness/specifications

• Order quantity

We provide transparent quotes with no hidden fees after reviewing your drawings/specs.