Custom Stamping Processing refers to the Specialized vestibulum ars, quod producit metallum components per stamping, inclinata, et welding secundum clientem speciei consilia. Using altus-qualis ferro laminas, processus involves praecisionem cum consuetudine, facta perit ad figura partes, sequitur CNC flectere ad accurate angulis et welding ad structural integritas. Tailored ad unicum requisitis, quod sustinet OEM / ODM projects, accipiens blueprints, cad files, aut exempla creare bespoke solutions. Specimen pro Automotive, Electronics, aut Industrial Applications, id ensures dimensional accurate, diuturnitatem, et aesthetic finit (eg, rubrum pictura). Custom Stamping Emhasizes flexibilitate, celeri prototyping, et sumptus-efficientiam pro humilis-medium volumen productionem, occurrens exactibus eget et consilium specifications.

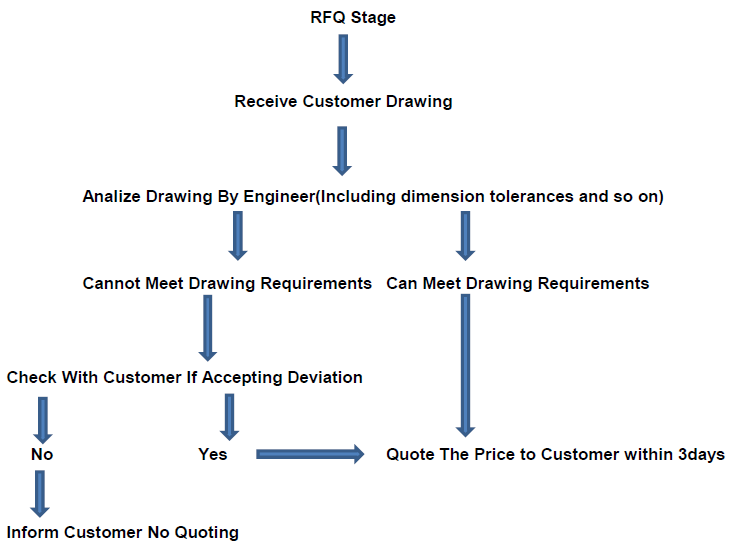

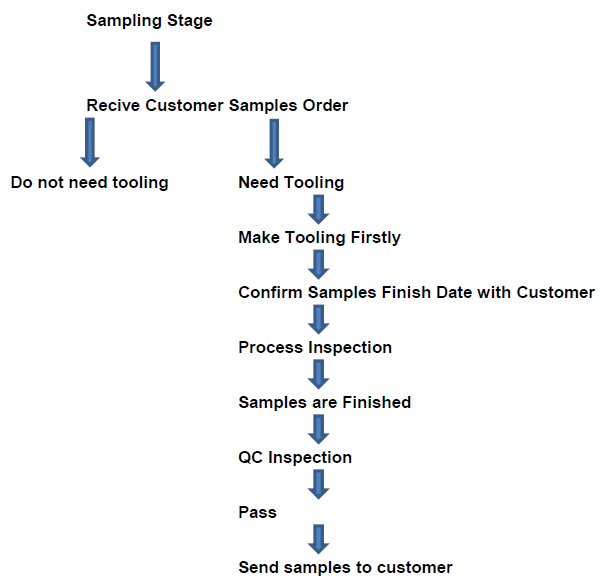

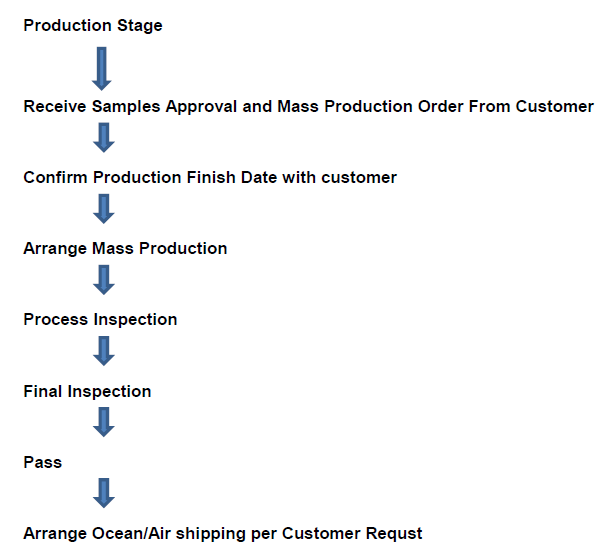

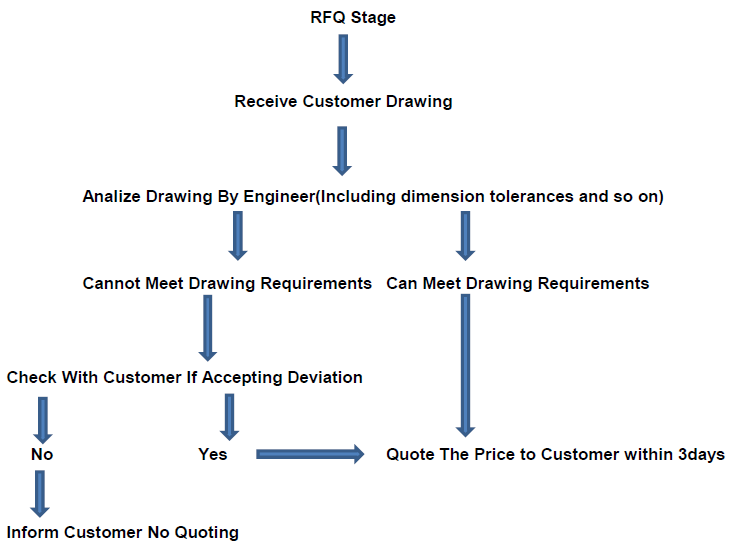

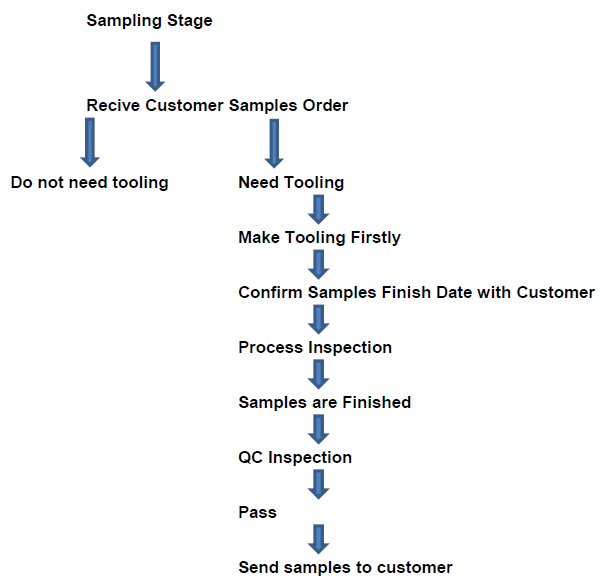

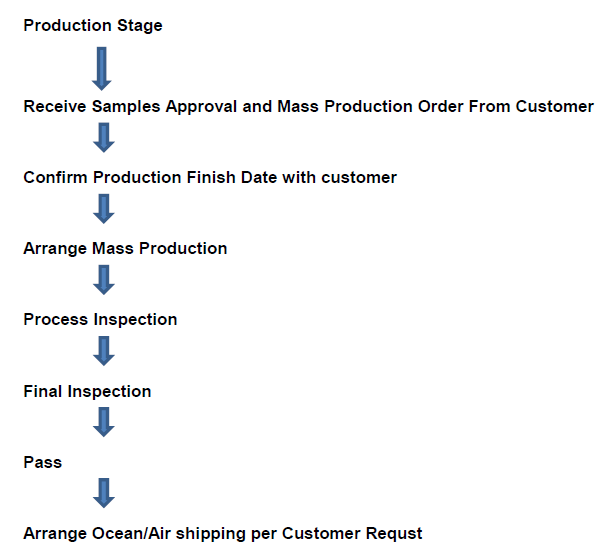

Nostrum opus fluxus chart pro customized Stamp Flectentes products ut infra:

Product commodum de Stamping Bending Welding Box:

Highly customized, accurate matching requirements: According to the drawings or design requirements provided by customers, flexible adjustment of product size, shape, function (such as opening, flanging, hinge connection, etc.), perfect for specific application scenarios, to solve the pain points of non-standard parts.

High-qualitas materiae, plerumque uti summus vires ferro (ut frigus, advolvit ferro, galvanized ferro, etc), combined cum superficie curatio (ut spargit, ut amplio rufus, et pulchritudinem.

Precisione Processus: Stamping (High-Certain Formation Formatio), CNC Tending (Angulus Error ≤0.5 °), laser welding (seamless, ut in productum mole est accurate, firmum, ut in productum mole est accurate, firmum, ut in occursum industriae vires.

Custus Efficens: Support parva batch ad altum volumen productio vitare redundant inventory of standardized products; Reducere materia vastum et altiore sumptus ex optimizing layout et processum catenam.

Fast responsio et partus: confidunt in digital productio processus (CAD / Cam consilio, automated processui), ex drawing Confirmationis ad complevit productum partus tempus brevis, maxime idoneam ad urgente ordines et iterative progressionem necessitates.

Controllable qualitas, reliable euismod: omnis processus qualis inspectionem (ut dimensiva tolerantia temptationis, weld vires temptationis) ut productum constantiam; Welding partes absque bullae, welding, inclinans sine rimas, diu term usus absque deformatio.

Design DECORTIO et intellectualis Property tutela: Strict Imperium of Customer Drawings et Notitia in customized processus vitare Design Outflow, praesertim pro patented products vel diversificant competitive necessitates.

Suscipe innovation et iteration: cooperari cum customers 'investigationis et progressionem necessitates providere proofing et celeri fusa reparatione officia ad massa productio.

Custom Stamping et Tendentes Welding products per 'productio in demanda ' mode, flexibilitate, praecisione, pretium et adputabilitatem et specie ad amplio apparatu et in foro competitiveness ad amplio elit et in foro competitiveness.

Product usum de Stamping Bending Welding Box:

Automotive industria

Partibus vestibulum, corpus bracket, chassis structuram, altilium arca, exhaurit pipe, cardine, ostium interiorem laminam etc.

Novum Energy Field: Electric vehiculo altilium Tray, præcipiens acervum testa, motor protectionem operimentum, etc.

Electronics et appliances

Equipment Crusta: Servo Chassis, Iter Crusta, Suspendisse, SwitchGear, distribution Box, etc.

Precision Partes: Iungo bracket, electro scutum, sensorem fastener, etc.

Equipment Industrial

Mechanica structuram partibus: Automation Equipment Frame, TRADUCTOR bracket, robot tutela operimentum, fixture, etc.

Repono et translationem apparatu: repono crusta, logistics turnover boxes, instrumentum cabinets, forklift accessiones, etc.

Architecture et ornamentum

Steel structuram: VENTILATIO DUCT, sagum Wall Support, Custom Guardrail, Stair Handrail, etc.

Eget components: Fireproof ostium frame, elevator car components, solaris firmamentum, etc.

Medical apparatu

Certamini instrumenta: Medical lectum bracket, chirurgicam instrumentum tray, apparatu tutela operimentum, mobile trolley frame, etc.

Consumer bona et partum consilio

Custom Supellecture: Classical Bookshelves, exornantur partitiones, lucerna uncis, etc.

Creative Products: Ars Installations, Display Props, personalized Signage, etc.

Utrum sit industrialis-gradus summus viribus components vel dolor products cum princeps aesthetic requisitis, customized Stamping Finentes Welding technology potest providere targeted solutions.

Packaging:

FAQ:

1Q: Quid materiae potest esse in stampadium processus?

1a: ferro, aluminium, aes, aeris et sic est.

2Q: Numquid non est MOQ huius generis nativus partibus?

2a: Sic, ibi est. Non pendeat a rudis materia pondus iussit.

3Q: Quousque enim productio cycle accipere?

3A: Ordinarius exolvuntur: Ex Drawing Confirmationis ad partum solet XXV dies (including fingunt faciens, iudicium productio, qualis inspectionem).

4Q: Utrum sustinere consilium optimization vel providere structural consilium?

4a: Cost Optimization: Africa materiae vel simpliciores processibus sunt suadetur (ut welding loco complexu flexione). Modus cooperantem: providebit sketches et conceptum drawings et fabrica scriptor fabrum potest auxilium conflentur Design Details.

5Q: Quam ad agam cum qualis problems post venditionem?

5A: Nos rework vel redo gratis. Nos analyze rationes et exitus tradit; agere solution (replenishment, instaurabo vel ultricies) .preventive mensuras: technica consensu debet esse signati et exempla signati ante massa productionem.