Custom Stamping Processing refers to the specialized manufacturing technique that produces metal components through stamping, bending, and welding based on client-specific designs. Using high-quality steel sheets, the process involves precision stamping with custom-made dies to shape parts, followed by CNC bending for accurate angles and welding for structural integrity. Tailored to unique requirements, it supports OEM/ODM projects, accepting blueprints, CAD files, or samples to create bespoke solutions. Ideal for automotive, electronics, or industrial applications, it ensures dimensional accuracy, durability, and aesthetic finishes (e.g., red painting). Custom stamping emphasizes flexibility, rapid prototyping, and cost-efficiency for low-to-medium volume production, meeting exact functional and design specifications.

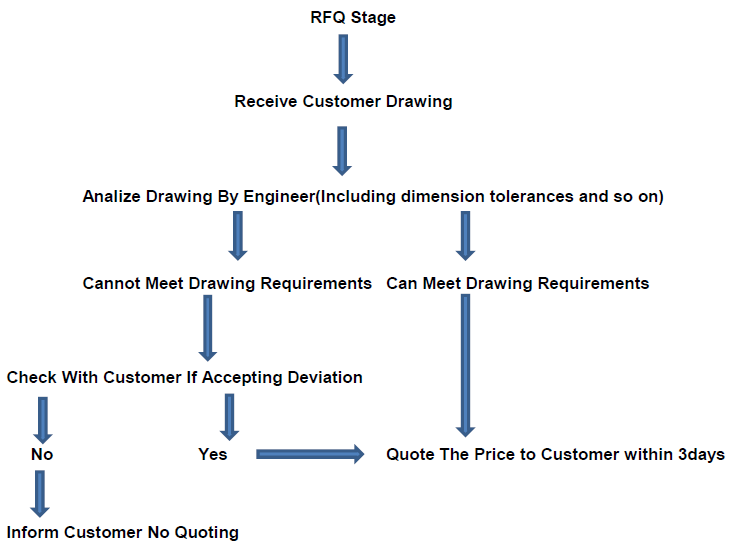

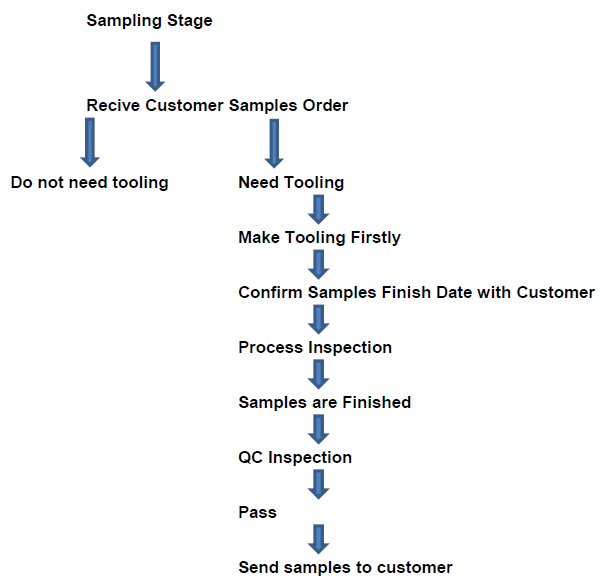

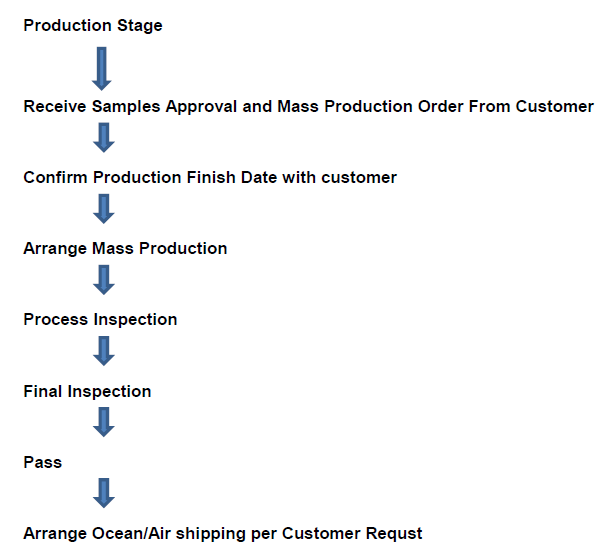

Our work flow chart for the customized stamping bending products as belows:

![RFQ阶段 RFQ阶段]()

![samples阶段 samples阶段]()

![production阶段 production阶段]()

Product Advantage of Stamping Bending Welding Box:

Highly customized, accurate matching requirements: According to the drawings or design requirements provided by customers, flexible adjustment of product size, shape, function (such as opening, flanging, hinge connection, etc.), perfect for specific application scenarios, to solve the pain points of non-standard parts.

High-quality materials: Usually use high-strength steel (such as cold-rolled steel, galvanized steel, etc.), combined with surface treatment (such as spraying, electroplating, red paint rust prevention), to improve corrosion resistance and beauty.

Precision process: stamping (high-precision mold forming), CNC bending (Angle error ≤0.5°), laser welding (seamless connection) and other technology combination, to ensure that the product size is accurate, stable structure, to meet the industrial strength requirements.

Cost effective: Support small batch to high volume production to avoid redundant inventory of standardized products; Reduce material waste and overall cost by optimizing the layout and process chain.

Fast response and delivery: Rely on digital production process (CAD/CAM design, automated processing), from drawing confirmation to finished product delivery time is short, especially suitable for urgent orders or iterative development needs.

Controllable quality, reliable performance: Whole process quality inspection (such as dimensional tolerance testing, weld strength testing) to ensure product consistency; Welding parts without bubbles, welding, bending without cracks, long-term use without deformation.

Design confidentiality and intellectual property protection: Strict control of customer drawings and data in customized processing to avoid design outflow, especially for patented products or differentiated competitive needs.

Support innovation and iteration: Cooperate with customers' research and development needs to provide proofing and rapid mold repair services to accelerate the transformation of products from design to mass production.

Custom stamping and bending welding products through the "production on demand" mode, flexibility, precision, cost control balance, especially suitable for the functional, compatibility or appearance of the demanding industrial areas, is the ideal choice to improve equipment performance and market competitiveness.

Product use of Stamping Bending Welding Box:

Automotive Industry

Parts Manufacturing : body bracket, chassis structure, battery box, exhaust pipe, hinges, door inner plate, etc.

New energy field : electric vehicle battery tray, charging pile shell, motor protection cover, etc.

Electronics and Appliances

Equipment shell : server chassis, router shell, heat sink, switchgear, distribution box, etc.

Precision parts: connector bracket, electromagnetic shield, sensor fastener, etc.

Industrial equipment

Mechanical structure parts : automation equipment frame, conveyor bracket, robot protective cover, fixture, etc.

Storage and transportation equipment: storage shelves, logistics turnover boxes, tool cabinets, forklift accessories, etc.

Architecture and Decoration

Steel structure: ventilation duct, curtain wall support, custom guardrail, stair handrail, etc.

Functional components: fireproof door frame, elevator car components, solar support, etc.

Medical equipment

Precision instruments : medical bed bracket, surgical instrument tray, equipment protective cover, mobile trolley frame, etc.

Consumer Goods and Creative Design

Custom furniture: metal bookshelves, decorative partitions, lamp brackets, etc.

Creative products : art installations, display props, personalized signage, etc.

Whether it is industrial-grade high-strength components or consumer products with high aesthetic requirements, customized stamping bending welding technology can provide targeted solutions.

Packaging:

![包装组图_meitu_3 包装组图_meitu_3]()

FAQ:

1Q: What materials can be used in stamping process?

1A: steel, aluminum, brass, copper and so on.

2Q: Is there MOQ for this kind of customized parts?

2A: yes, there is. It depends on the raw material weight ordered.

3Q: How long does the production cycle take?

3A: Regular cycle: From drawing confirmation to delivery usually takes 25 days (including mold making, trial production, quality inspection).

4Q: Does it support design optimization or provide structural advice?

4A: Cost optimization: Alternative materials or simplified processes are recommended (e.g. welding instead of complex bending). Cooperative mode: Provide sketches or concept drawings, and the manufacturer's engineers can help refine the design details.

5Q: How to deal with quality problems after sale?

5A: We rework or redo free of charge. We analyze the reasons and issue reports;Negotiate a solution (replenishment, repair or compensation).Preventive measures: Technical agreement must be signed and samples sealed before mass production.